Pulse valves are essential components in modern industrial filtration systems, particularly in dust collection applications. They play a crucial role in the effective cleaning and regeneration of filter bags, ensuring maximum efficiency and extended service life. In this comprehensive guide, we will delve into the inner workings of pulse valves, exploring their design, functionality, and applications. We will also discuss the latest trends and advancements in pulse valve technology, with a special focus on the high-quality solutions offered by Suzhou XieChang Environmental Protection Technology Co., Ltd.

What is a Pulse Valve?

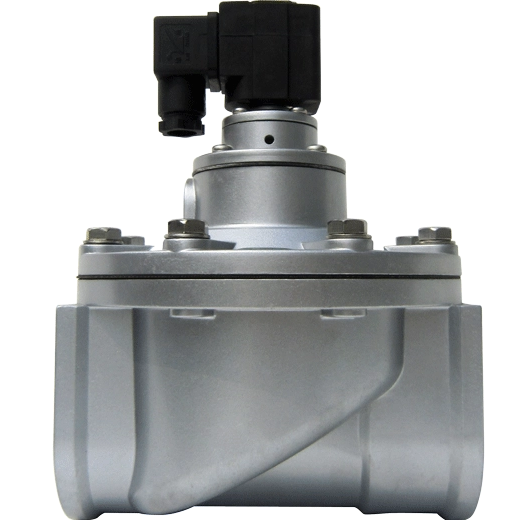

A pulse valve is a specialized type of solenoid valve designed to deliver short bursts or pulses of compressed air. Unlike traditional solenoid valves that provide continuous flow, pulse valves are engineered to release air in rapid, high-pressure bursts. This unique functionality makes them ideal for applications where a sudden, powerful blast of air is required, such as in dust cleaning systems for bag filters.

Key Features of Pulse Valves

High-Quality Materials: Pulse valves are typically made from durable materials such as cast aluminum, ensuring longevity and reliability.

Fast Opening and Closing: Pulse valves are designed to open and close rapidly, providing efficient and effective cleaning cycles.

Long Service Life: High-quality rubber diaphragms and robust construction ensure that pulse valves can withstand millions of cycles without degradation.

Energy Efficiency: By delivering powerful pulses of air in short bursts, pulse valves minimize energy consumption and reduce operational costs.

![DCF-T-50S正_520_520 DCF-T-50S正_520_520]()

Working Principle of Pulse Valves

Understanding the working principle of pulse valves is crucial for appreciating their effectiveness in industrial applications. Pulse valves operate based on the principles of electromagnetism and pressure differential.

Basic Components of a Pulse Valve

Electromagnetic Pilot Operator: This part includes the electromagnetic coil and armature. When energized, it controls the opening and closing of the discharge opening.

Diaphragm: The diaphragm is a flexible membrane that separates the front and back cavities. It has a small orifice that helps in damping the airflow.

Valve Body: This is the main structure that houses all the components and provides the necessary pathways for air flow.

How Does a Pulse Valve Work?

Closed Position: Under normal conditions, the diaphragm is pressed against the valve outlet by the pressure differential between the front and back cavities, keeping the valve closed.

Opening the Valve: When an electric signal from a controller energizes the electromagnetic coil, the armature moves to open the discharge opening in the back cavity. This allows the compressed air in the back cavity to escape, reducing the pressure there. As a result, the higher pressure in the front cavity pushes the diaphragm upward, opening the main outlet of the valve. The valve then starts to blow air.

Closing the Valve: When the electric signal is removed, the spring in the pilot operator pushes the armature back to its original position, closing the discharge opening. The pressure in the front cavity, combined with the spring force, pushes the diaphragm back down to close the passage, stopping the airflow.

Double Diaphragm Pulse Valves

Double diaphragm pulse valves offer enhanced performance compared to single diaphragm valves. These valves have an additional small diaphragm that vents the air above the main diaphragm, creating a more rapid pressure differential and resulting in a more powerful and quicker pulse.

Advantages of Double Diaphragm Valves

Increased Shock Intensity: The double diaphragm design provides a more severe shock, affecting more filter bags (up to 40% more).

Longer Diaphragm Life: The design reduces wear on the diaphragms, extending their lifespan.

Energy Efficiency: By providing powerful pulses at longer intervals, these valves reduce overall energy consumption and save on compressed air.

Pulse valves are widely used in various industries where dust accumulation and filtration are critical. Some common applications include:

Cement and Concrete Plants

In cement and concrete plants, pulse valves are used to clean bag filters, ensuring efficient dust removal and maintaining optimal operational conditions. The powerful pulses of air effectively shake off accumulated dust, preventing clogging and extending the life of the filter bags.

Ceramics and Glass Industries

In the ceramics and glass industries, pulse valves play a vital role in maintaining clean environments. They are used to prevent dust accumulation on filter bags, ensuring efficient filtration and reducing the risk of contamination.

Feed and Thermal Power Plants

Feed and thermal power plants rely on pulse valves to prevent dust buildup in bag filters. The high-pressure pulses of air effectively remove dust particles, ensuring smooth operation and minimizing downtime.

Detergent and Iron and Steel Industries

In the detergent and iron and steel industries, pulse valves are used to prevent dust solidification in bunkers. The powerful pulses of air keep the dust loose, ensuring efficient removal and preventing blockages.

![Steel Industries Steel Industries]()

Installation and Control

Proper installation and control are essential for ensuring the optimal performance of pulse valves. Here are some key considerations:

Direct Mounting vs. Separate Coil Mounting

Pulse valves can be installed using either direct mounting or separate coil mounting methods. Direct mounting involves attaching the coil directly to the valve body, while separate coil mounting involves placing the coil in a separate enclosure, often an aluminum box. Separate coil mounting offers better protection against environmental factors such as water, dust, and fluids.

Control Mechanisms

Pulse valves are typically controlled by time relays or differential pressure relays. Time relays allow for adjustable burst times and intervals, ensuring precise control over the cleaning cycles. Differential pressure relays monitor the pressure difference across the filter bags and activate the pulse valves as needed to maintain optimal filtration efficiency.

Maintenance and Troubleshooting

Regular maintenance is essential for ensuring the longevity and reliability of pulse valves. Here are some key maintenance tips and troubleshooting solutions:

Regular Maintenance Tips

Inspect for Wear and Tear: Regularly inspect the diaphragms and other components for signs of wear and tear. Replace any damaged parts promptly.

Clean the Valves: Periodically clean the valves to remove any accumulated dust or debris. This helps maintain optimal performance and prevents clogging.

Check Electrical Connections: Ensure that all electrical connections are secure and free from corrosion. Loose or corroded connections can affect the performance of the valves.

Common Issues and Solutions

Leaking Valves: If a valve is leaking, check for damaged diaphragms or loose connections. Replace any damaged parts and tighten all connections.

Inconsistent Pulses: Inconsistent pulses can be caused by low air pressure or faulty time relays. Check the air pressure and replace any faulty relays.

Failure to Open or Close: If a valve fails to open or close, inspect the electromagnetic coil and armature for damage. Replace any damaged components and ensure that the valve is properly energized.

FAQ: Frequently Asked Questions about Pulse Valves

What are the key features of pulse valves?

A: Key features of pulse valves include high-quality materials (such as cast aluminum), fast opening and closing mechanisms, long service life due to durable rubber diaphragms, and energy efficiency through short bursts of air.

How does a pulse valve work?

A: Pulse valves operate based on the principles of electromagnetism and pressure differential. When an electric signal energizes the electromagnetic coil, the armature moves to open the discharge opening in the back cavity, allowing compressed air to escape and creating a pressure imbalance. This imbalance causes the diaphragm to lift, opening the main outlet and releasing a pulse of air. When the signal is removed, the valve closes, and the diaphragm returns to its original position.

In which industries are pulse valves commonly used?

A: Pulse valves are widely used in industries such as cement and concrete plants, ceramics and glass industries, feed and thermal power plants, detergent manufacturing, and iron and steel industries. They are essential for cleaning bag filters and preventing dust accumulation.

How do pulse valves help in maintaining filter bags in dust collection systems?

A: Pulse valves deliver powerful bursts of compressed air that shake off accumulated dust from the filter bags, preventing clogging and extending the life of the bags. This ensures efficient dust removal and maintains optimal operational conditions in dust collection systems.

Conclusion

Pulse valves are indispensable components in modern industrial filtration systems, providing efficient and effective cleaning solutions for bag filters. With their unique ability to deliver powerful pulses of air in short bursts, pulse valves ensure maximum filtration efficiency and extended service life of filter bags. By understanding the working principle, types, and applications of pulse valves, you can make informed decisions when selecting and installing these critical components.

At Suzhou XieChang Environmental Protection Technology Co., Ltd., we are committed to providing high-quality pulse valves and related accessories. Our state-of-the-art solutions are designed to meet the most demanding industrial requirements, ensuring optimal performance and reliability. For more information on our pulse valve offerings and other dust collection solutions, visit our website or contact our sales team.