A Pulse Jet Dust Collector is a powerful air filtration system designed to capture fine dust, fumes, and particulate matter in industrial environments. These collectors use high-pressure air pulses to clean filter bags automatically, ensuring continuous operation and minimal downtime. Industries from cement and asphalt plants to pharmaceuticals and food processing rely on them for cleaner air and safer workplaces. In this guide, we’ll explore how pulse jet dust collectors work, their types, benefits, and practical applications to help you choose the right system for your facility.

![Pulse Jet Bag Dust Collector Pulse Jet Bag Dust Collector]()

Types of Pulse Jet Dust Collectors

Pulse jet dust collectors come in many shapes and configurations, each designed to handle specific industrial challenges. They can capture fine dust, fumes, and heavy particulate, depending on the application. Let’s take a closer look at the main types.

Cylindrical Pulse Jet Dust Collectors

These collectors are perfect for high-volume, explosion-prone environments. They usually feature a tangential inlet that spins incoming dust, separating larger particles before reaching the filter. Many models use dual-stage separation, which improves filtration and reduces maintenance.

Key features:

They are common in cement plants, power plants, and metal processing where both safety and efficiency matter.

Modular Pulse Jet Dust Collectors

Modular systems are all about scalability and flexibility. You can add modules as your facility grows or your production needs change. Optional features include HEPA filters for ultra-fine dust, explosion venting, and automated monitoring systems.

Benefits:

Easy to expand or customize

Supports various dust types

Can include automated pulse cleaning

These units are great for growing facilities that need reliable performance without redesigning the whole system.

Cartridge Pulse Jet Dust Collectors

Cartridge collectors are compact and use pleated cartridge filters. This design increases the surface area for dust capture while keeping the footprint small. They handle fine particles, smoke, and fumes efficiently, making them ideal for pharmaceutical, electronics, or welding applications.

Advantages:

High filtration efficiency

Low maintenance requirements

Compact, space-saving design

Air Box Style Pulse Jet Dust Collectors

Air box collectors combine pulse jet cleaning with backflushing, giving excellent dust removal in heavy-duty environments. They are suited for industries where dust loads are high and continuous cleaning is critical.

Applications:

They are robust and designed to keep filters performing efficiently under challenging conditions.

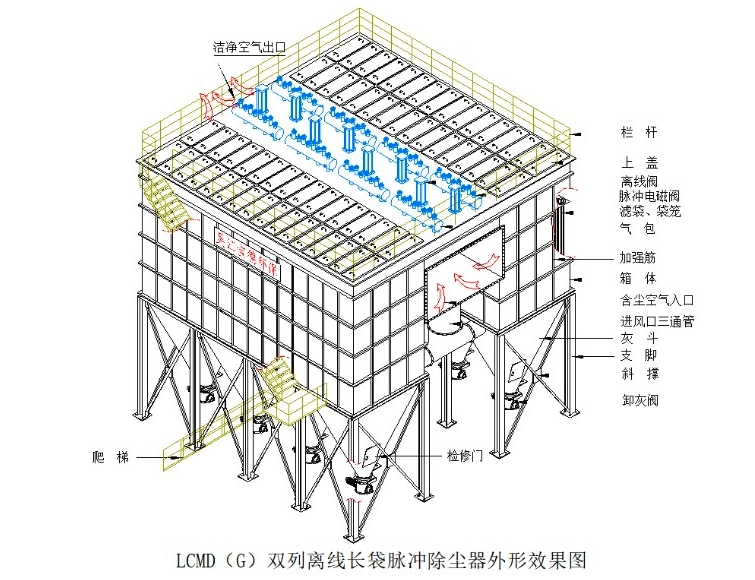

Offline System Pulse Jet Dust Collectors

Offline systems isolate the cleaning cycle from airflow, so dust removal doesn’t interfere with production. They are especially useful in chemical plants and coal-fired boiler operations, where constant emissions control is required.

Key points:

Bin Vent Pulse Jet Dust Collectors

Bin vent collectors are compact and usually installed on silos, hoppers, and bucket elevators. They help control dust during material transfer or storage, keeping the environment cleaner and safer.

Features:

Fume Style Pulse Jet Dust Collectors

Fume collectors target ultra-fine particles and smoke, commonly from welding, soldering, or chemical processes. Many models include spark-proof features and explosion venting for added safety.

Highlights:

Efficient at removing smoke and fumes

Spark-proof options

Explosion venting available

Perfect for labs or high-risk production areas

Comparison Table of Pulse Jet Dust Collector Types

| Type | Best For | Key Features | Typical Industry |

| Cylindrical | High-volume, explosive dust | Tangential inlet, dual-stage | Cement, metal, power |

| Modular | Growing facilities | HEPA, venting, monitoring | Chemical, food, pharmaceuticals |

| Cartridge | Fine dust/fumes | Pleated filters, compact | Electronics, welding, pharma |

| Air Box | Heavy-duty cleaning | Backflushing, pulse jet | Mining, steel, manufacturing |

| Offline | Continuous process | Isolated cleaning cycles | Coal plants, chemical |

| Bin Vent | Material transfer | Compact, efficient | Silos, hoppers, elevators |

| Fume Style | Ultra-fine smoke | Spark-proof, vented | Welding, chemical, lab |

Key Benefits of Pulse Jet Dust Collectors

Pulse jet dust collectors are more than just filters—they improve air quality, efficiency, and safety across industrial facilities. Let’s break down the main advantages.

High Dust Removal Efficiency

These systems capture even the finest particles, often as small as 0.5–1 micron. Dust and fumes are trapped before they can escape, keeping the workplace cleaner and reducing environmental emissions.

Highlights:

Efficient capture of ultra-fine dust

Reduces airborne contaminants

Supports cleaner air for employees and machinery

This makes them ideal for pharmaceutical, food, and chemical processing, where air quality is critical.

Energy Savings

Pulse jet systems are designed to minimize energy use. Compared to reverse-air baghouses, they operate at lower pressure drops, and compressed air is only used in short, targeted bursts during cleaning.

Energy advantages:

Reduced fan power consumption

Optimized pulse cleaning cycles

Lower operating costs over time

These features help facilities save money while maintaining high filtration performance.

Continuous Operation and Minimal Downtime

One of the biggest perks is online cleaning. Filters are cleaned while the system runs, so production doesn’t need to stop. Regular pulse cleaning also prevents filter clogging, which extends filter life.

Key points:

Continuous operation for uninterrupted production

Pulse cleaning preserves filter integrity

Less frequent maintenance required

This is especially useful in cement plants, steel mills, and coal-fired power plants.

Regulatory Compliance

Pulse jet collectors help companies meet strict air quality standards. They are engineered to comply with EPA, OSHA, and ISO regulations, ensuring both employee safety and environmental responsibility.

Compliance benefits:

Captures regulated pollutants like particulate matter

Supports legal and environmental reporting

Maintains safe working conditions

Increased Productivity

A clean workspace directly affects productivity. Dust buildup can clog equipment, slow down machinery, or force shutdowns. Pulse jet collectors keep dust under control and production running smoothly.

Productivity gains:

Prevents equipment fouling

Reduces downtime for cleaning

Keeps processes efficient

Product Quality Improvement

Sensitive manufacturing processes, especially in electronics, pharmaceuticals, and food, can be easily contaminated by dust. Pulse jet systems protect products, ensuring high-quality output and fewer rejects.

Quality advantages:

Protects against airborne contamination

Maintains consistent production standards

Improves final product reliability

Common Applications of Pulse Jet Dust Collectors

Pulse jet dust collectors are widely used across industries that need clean air and safe working conditions. Their high efficiency makes them ideal for capturing fine dust and particulate matter, protecting both workers and machinery.

Cement and Asphalt Plants

In cement and asphalt production, pulse jet dust collectors handle kiln exhaust and clinker dust. These fine particles can damage equipment and create hazardous working conditions if left uncontrolled. By capturing dust at the source, these collectors help reduce airborne contamination, protect machinery, and maintain compliance with air quality regulations.

Power Generation

Coal-fired power plants and industrial boilers produce fly ash and exhaust gases that must be removed to prevent environmental and equipment issues. Pulse jet dust collectors trap these particles before they leave the stacks, reducing wear on turbines and fans while helping facilities meet EPA and local emissions standards.

Metal and Steel Processing

Metalworking and steel production generate furnace gases, welding fumes, and fine dust. Pulse jet dust collectors capture these contaminants efficiently, improving air quality and reducing fire risks. They are particularly valuable in foundries, welding shops, and cutting or grinding operations, where dust and smoke could otherwise pose serious health hazards.

Pharmaceutical Industry

Pharmaceutical manufacturing often involves handling fine powders and venting gases from reactors or mixers. Pulse jet dust collectors prevent these particles from escaping into production areas, minimizing cross-contamination risks. By maintaining cleaner air, they support sterile environments and help facilities meet strict ISO and cleanroom standards.

Food Processing

Dust from flour, sugar, spices, and other powdered ingredients can create hygiene issues and health risks. Pulse jet dust collectors remove these airborne particles, keeping workspaces clean and reducing product loss. They also help facilities maintain compliance with food safety regulations and protect employees from inhaling fine powders.

| Industry | Typical Dust/Particle | Why Use Pulse Jet Collectors |

| Cement & Asphalt | Kiln exhaust, clinker dust | Reduces machinery wear, controls emissions |

| Power Generation | Fly ash, boiler exhaust | Keeps fans and turbines clean, lowers emissions |

| Metal & Steel | Furnace gases, welding fumes | Protects workers, reduces fire risks |

| Pharmaceutical | Powder handling, reactor venting | Maintains clean production areas, reduces contamination |

| Food Processing | Flour, sugar, spices | Supports hygiene, prevents airborne contamination |

![Applications of Pulse Jet Dust Collectors Applications of Pulse Jet Dust Collectors]()

Maintenance Tips for Maximum Efficiency

Regular Inspections

Check filter bags for tears, holes, or wear. Inspect cages to ensure they keep their shape during operation. Verify pulse valves are working correctly and compressed air lines are free from leaks or blockages. Regular checks prevent sudden drops in efficiency and minimize downtime.

Pulse Pressure Optimization

Adjust the air pulse pressure according to the dust load. Too high pressure can damage or shorten filter bag life. Too low pressure leaves dust cake on the filter. Proper optimization ensures thorough cleaning without stressing the system.

Monitor Differential Pressure

Keep an eye on pressure differences between the clean and dirty sides of the collector. A sudden increase may indicate clogged filters, while a drop could signal bag damage or holes. Monitoring differential pressure helps catch issues early.

Scheduled Hopper Cleaning

Empty the dust collection hopper regularly. Dust can form bridges or re-enter the airflow if left unattended. Scheduled cleaning ensures smooth dust flow and prevents re-entrainment into the system.

Filter Replacement

Replace worn-out filter bags according to dust type and operating conditions, typically every 2–5 years. Timely replacement maintains high collection efficiency and protects both equipment and personnel from harmful dust.

FAQ

Q: What types of filters are used in pulse jet dust collectors?

A: Pulse jet dust collectors use bag filters and pleated cartridge filters made from polyester, PTFE, fiberglass, aramid, PPS, polypropylene, or acrylic, tailored to handle specific temperatures, chemicals, and dust types.

Q: Which industries benefit most from pulse jet dust collectors?

A: Industries such as cement, asphalt, power generation, metal and steel processing, pharmaceuticals, food processing, woodworking, plastic/resin processing, and paper manufacturing benefit from their high-efficiency dust removal.

Q: How long do pulse jet bag filters last?

A: Typical pulse jet bag filters last 2–5 years, depending on dust type, operating conditions, and proper maintenance.

Q: How does a pulse jet dust collector compare to a reverse air baghouse?

A: Pulse jet collectors clean with high-pressure air pulses, offering higher efficiency, lower energy use, minimal downtime, and a compact footprint, while reverse air baghouses use slower, low-pressure airflow and require more frequent maintenance.

Conclusion

Pulse jet dust collectors are more than just industrial filters—they actively improve air quality, protect equipment, and keep production running smoothly. From handling ultra-fine powders in pharmaceuticals to heavy dust in cement plants, they adapt to diverse industrial challenges while saving energy and reducing downtime.

At Suzhou XIECHANG Environmental Protection Technology Co., LTD, we provide tailored pulse jet dust collection solutions designed to meet your facility’s unique needs. Explore our systems to boost efficiency, comply with regulations, and create a safer, cleaner workplace today.