Choosing the right dust collector filter bag safeguards your facility. It improves air quality and protects employees from hazardous dust. A high-quality dust collector filter bag prevents damage to machinery and reduces maintenance costs. Superior filters help your business meet air quality standards and lower the risk of fire or explosion. CPE Filters offers custom solutions that match your needs. Assess your facility’s requirements to make the best choice for safety and performance.

Key Takeaways

Identify the type of dust your facility generates. Different dust types require specific filtration approaches for safety and efficiency.

Choose the right filter bag material based on your operating conditions. Polyester, aramid, polypropylene, and PTFE each have unique benefits.

Select the correct bag size and configuration. Proper dimensions ensure efficient dust capture and easy installation.

Understand the operating conditions of your facility. Temperature, moisture, and chemical exposure impact filter performance.

Monitor micron ratings for filtration efficiency. Lower ratings capture smaller particles, improving air quality and equipment protection.

Implement a regular maintenance schedule. Frequent inspections and cleaning extend filter life and maintain system efficiency.

Ensure compliance with industry standards. Meeting OSHA, NFPA, and ISO requirements protects workers and avoids penalties.

Consult experts like CPE Filters for tailored solutions. Their guidance helps you select the best filter for your unique needs.

Identify Dust Type & Application

Selecting the right dust collector filter bag starts with knowing the type of dust your facility generates. Each dust type presents unique risks and requires a specific approach to filtration. CPE Filters specializes in matching the right dust collector bag filter to your application, ensuring safety and compliance.

Common Dust Types

Wood

Metal

Chemical

Chemical dusts, such as asbestos or silica, are hazardous.

Long-term exposure can lead to severe diseases, including cancer.

Food

Food dust can be sticky or fibrous, which may clog filters.

It often requires special filter treatments to prevent matting.

Mineral

Mineral dust, including silica and coal, can cause lung diseases.

Silica dust leads to silicosis and lung cancer if inhaled.

Tip: Always identify the specific hazards of your dust. For example, concrete and brick dust contain crystalline silica, which can cause silicosis. Rubber and plastic dusts are combustible and may release toxic chemicals.

Application Impact

![]()

Manufacturing

Manufacturing environments produce a wide range of dust, from fine powders to coarse particles. The dust collector filter must match the particle size and behavior to ensure efficient capture and easy cleaning.

Construction

Construction sites often generate mineral and silica dust. These particles are dangerous and require a dust collector filter with high filtration efficiency and durability.

Processing

Processing plants handle food, chemicals, and other materials. Sticky or moist dust can adhere to filter media, so facilities need specially treated filters to maintain performance.

Energy

Energy production can create coal, metal, and mineral dust. These environments demand filters that withstand high dust loading and potential combustibility.

Understanding the characteristics of your dust—such as particle size, moisture content, texture, and combustibility—directly impacts your filter choice. Fine, dry dust may need a different filter than coarse or sticky dust. Moist dust requires special finishes to prevent clogging. Combustible dusts need flame-retardant or conductive filter media to reduce explosion risks.

CPE Filters offers expert guidance and custom solutions for every application. Trust their experience to help you select the best dust collector filter for your facility’s unique needs.

Choose Dust Collector Filter Bag Material

Selecting the right material for your dust collector filter bag is essential. The material determines how well the filter performs under different conditions. CPE Filters offers a wide range of synthetic and natural fiber options, ensuring you find the best fit for your facility.

Material Options

Choosing the correct material depends on your dust type, operating temperature, and chemical exposure. Each material brings unique benefits to your dust collector system.

Polyester

Polyester is a popular choice for many industries. It resists dry heat, chemicals, and abrasion. This material works well in environments with moderate temperatures and dry dust. Polyester filter bags balance durability with fine dust capture, making them ideal for manufacturing and processing plants. However, polyester is not suitable for humid environments.

Aramid

Aramid filter bags withstand high temperatures and offer excellent resistance to abrasion. They perform well in energy production and metalworking facilities. Aramid is a strong option when your dust collector faces extreme heat or heavy dust loading.

Polypropylene

Polypropylene filter bags resist moisture and chemicals. This material is perfect for facilities where dust contains sticky or wet particles. Polypropylene also offers hydrophobic properties, making it a smart choice for food processing and chemical plants.

PTFE

PTFE, also known as Teflon, stands out for its superior chemical resistance and ability to handle high temperatures. PTFE filter bags are ideal for environments with acids, alkalis, or aggressive chemicals. They also enhance cleaning cycle efficiency, reducing maintenance downtime.

Acrylic

Acrylic filter bags provide moderate chemical resistance and perform well in low-temperature applications. They suit facilities where dust is not highly abrasive or where chemical exposure is limited.

Tip: Always match the filter bag material to your facility’s operating conditions. The right choice improves filtration efficiency and extends the life of your dust collector bag filter.

Material Selection Guide

Temperature and chemical resistance play a critical role in material selection. CPE Filters helps you evaluate these factors to ensure your dust collector filter operates safely and efficiently.

Below is a quick-reference chart to help you compare material options based on your application requirements:

Material Type | Advantages | Disadvantages |

Polyester | Resists dry heat, chemicals, and abrasion | Not suitable for humid environments |

Aramid | Withstands high temperatures, abrasion-resistant | Limited chemical resistance |

Polypropylene | Withstands moisture and chemicals | Not ideal for high heat |

PTFE | Superior chemical resistance, high-temperature stable | Higher cost |

Acrylic | Moderate chemical resistance, low-temperature use | Not for high heat or aggressive chemicals |

For facilities with high temperatures or aggressive chemicals, PTFE and aramid materials deliver superior performance. Polypropylene and acrylic work best in low-temperature or moist environments. Polyester offers a balance of durability and fine dust capture for general applications.

Criteria | High-Temperature Materials | Low-Temperature Materials | Chemical Resistance Materials |

Operating Temperature | Aramid, PTFE | Polyester, Polypropylene | PTFE, Polypropylene |

Chemical Environment | - | - | Superior chemical resistance |

Moisture Levels | - | - | Hydrophobic materials like PTFE, Polypropylene |

Bag Characteristic | Specification | Performance Benefit |

Fabric Material | Polyester felt | Balances durability with fine dust capture |

Seam Construction | Double-stitched, taped | Ensures leak-free operation under high pressure |

Micron Rating | 1–25 micron | Controls minimum particle size retention |

Anti-Static Properties | Conductive fiber overlay | Prevents dust clinging and reduces ignition risk |

PTFE Membrane Coating | Polytetrafluoroethylene | Enhances release and cleaning cycle efficiency |

CPE Filters provides expert guidance to help you select the best dust collector filter bag material. The right material improves air quality, reduces maintenance, and ensures compliance with safety standards. Contact CPE Filters for custom solutions that match your facility’s unique needs.

Bag Size & Configuration

Choosing the right bag size and configuration is essential for maximizing the performance of your dust collector filter bag. The correct dimensions and fit ensure efficient dust capture, easy installation, and long-lasting operation. CPE Filters offers custom sizing to match your system’s requirements.

Bag Size & Specs

Diameter

The diameter of your dust collector bag filter must match the cell plate dimensions of your dust collector. A proper fit prevents leaks and ensures optimal filtration. Standard diameters range from 4 to 8 inches, but custom sizes are available for unique systems.

Length

Bag length impacts the surface area available for filtration. Longer bags provide more cloth area, increasing dust collection efficiency. Typical lengths vary from 24 to 120 inches, depending on the application and space constraints. Always measure your collector’s housing to determine the best length.

Air-to-Cloth Ratio

The air-to-cloth ratio is a critical factor in dust collector filter performance. This ratio compares the airflow volume to the surface area of the filter media. Maintaining the right ratio prevents rapid clogging and reduces maintenance costs. A high ratio leads to quick filter blockage and increased energy use. A low ratio wastes space and resources. The optimal ratio depends on dust type, particle size, and collection goals. Balancing filter area and airflow extends filter life and boosts efficiency.

Tip: Consult CPE Filters for guidance on air-to-cloth ratio. Their experts help you select the ideal bag size for your dust collector, ensuring reliable operation and compliance.

Measurement Type | Details |

Cell Plate Dimensions | Required for proper fit |

Snapband Size | Essential for installation |

Flat Width or Diameter | Critical for sizing |

Bag Length | Important for functionality |

Specialty Features | Includes wear strips, loops, etc. |

Bag Shapes & Fit

Round

Round bags are the most common shape. They fit standard baghouse systems and provide uniform airflow. This shape is ideal for general industrial applications.

Flat

Flat bags suit compact collectors and tight spaces. They offer efficient filtration in systems with limited room for installation.

Envelope

Envelope bags maximize surface area in small collectors. Their design allows for high dust loading and easy cleaning.

Snap Band/Collar/Ring

Snap band, collar, or ring fittings ensure a secure seal between the bag and the collector. These features simplify installation and prevent leaks. Galvanized rings and sewn joints add durability and acid resistance.

Factor | Description |

Air-to-Cloth Ratio | Affects efficiency and filter lifespan |

Temperature | Determines suitable filter media type |

Chemistry | Protects against chemical damage |

Abrasion | Reduces wear from hard dust |

Particle Size | Requires specific filter types |

Combustibility | Ensures safety compliance |

OSHA Standards | Promotes workplace safety |

NFPA Guidelines | Minimizes combustible dust risks |

Selecting the right shape and fit guarantees that your dust collector filter operates at peak efficiency. CPE Filters provides custom solutions for every system, helping you achieve superior dust collection and workplace safety.

Operating Conditions for Dust Collector Filter

Selecting the right dust collector filter bag for your system means understanding the operating conditions inside your facility. Extreme temperatures, moisture, and chemical exposure can all impact filter performance. The wrong choice can lead to costly downtime, safety hazards, and reduced filtration efficiency. CPE Filters provides custom solutions designed to handle even the most demanding environments.

Temperature Resistance

High Heat

Industrial processes often generate high temperatures. Not every filter bag can withstand these conditions. Using a filter bag with insufficient temperature resistance can cause thermal degradation, filter failure, and even fires. You need a filter that matches your system’s heat demands.

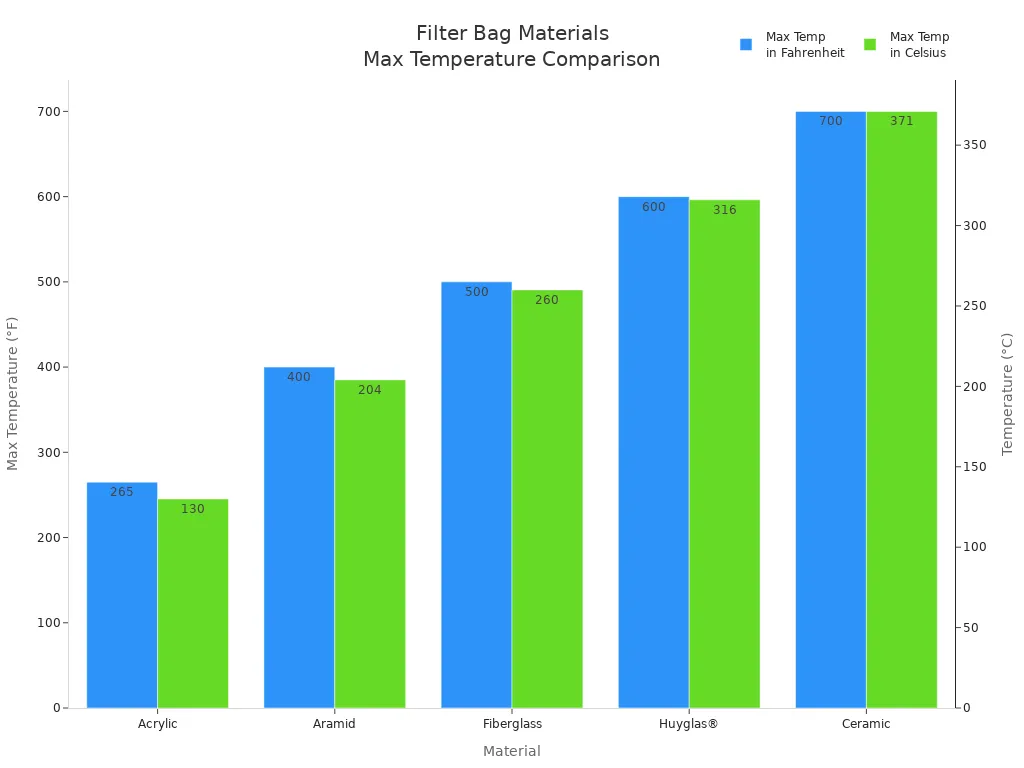

Material | Max Temperature (°F) | Max Temperature (°C) | Suitability |

Acrylic | 265 | 130 | High-temperature situations |

Aramid | 400 | 204 | Abrasion-resistant applications |

Fiberglass | 500 | 260 | High-temperature environments |

PTFE | N/A | N/A | Superior chemical resistance |

Huyglas® | 600 | 316 | High-performance applications |

Ceramic | 700 | 371 | Reverse-air and pulse-jet baghouses |

Note: Always match your filter material to your system’s maximum operating temperature. This step prevents overheating, filter breakdown, and safety risks.

If your process involves high heat, consider aramid, fiberglass, or ceramic filter bags. These materials resist extreme temperatures and maintain performance under stress. CPE Filters can help you select the best option for your dust collector.

Low Temp

Some facilities operate in low-temperature environments. Not all filter bags perform well in cold conditions. Acrylic and polyester materials work best for low temperatures. They maintain flexibility and filtration efficiency, even when the air is cold. Choosing the right material ensures your dust collector bag filter works reliably year-round.

Moisture & Chemical Exposure

Moisture-Resistant

Moisture in the air can change how dust behaves. High humidity can actually improve filtration by making dust particles stick together. However, too much moisture can cause filter clogging or reduce filter life. Polyester materials resist moisture and allow for effective cleaning cycles. For sticky or wet dust, CPE Filters offers special finishes that prevent matting and keep your system running smoothly.

Increased humidity can improve dust capture.

Moisture exposure can lower pressure drop and make cleaning easier.

Wet dust behaves differently than dry dust, so filter selection matters.

Tip: Always assess your facility’s humidity levels before choosing a filter bag. The right choice prevents clogs and extends filter life.

Chemical-Resistant

Chemical exposure can damage standard filter bags. Some dusts contain acids, alkalis, or solvents that break down filter media. For these environments, chemical compatibility is critical. PTFE and polypropylene materials offer superior resistance to harsh chemicals. These filters maintain their structure and performance, even in aggressive conditions.

Evaluate the types of chemicals present in your process.

Select filter materials that resist chemical attack.

CPE Filters provides custom solutions for unique chemical environments.

Alert: Never use a standard filter bag in a chemical-rich environment. Always choose a filter designed for chemical compatibility to protect your equipment and employees.

Why CPE Filters?

CPE Filters understands that every facility faces unique challenges. Their experts help you evaluate temperature, moisture, and chemical risks. With custom dust collector bag filter solutions, you get the right fit for your system and peace of mind for your team.

Filtration Efficiency & Maintenance

Best Dust Collector Performance

Micron Ratings

The micron rating of a dust collector bag filter shows the smallest particle size it can capture. Lower micron ratings mean higher filtration efficiency because the filter traps even the tiniest particles. Most filter bags have ratings from 1 to 200 microns. For example, polypropylene and polyester materials offer different levels of high filtration efficiency based on their design. Choosing the right micron rating protects your equipment and keeps your air clean.

Tip: Select a filter bag with a micron rating that matches your dust type. This ensures the best dust collector performance and keeps your facility safe.

Airflow

Airflow is the amount of air that moves through your dust collector. Good airflow means your system works efficiently and collects dust without clogging. As dust builds up on the filter, resistance increases. This resistance is called pressure drop. If pressure drop gets too high, your system uses more energy and costs go up. Regular cleaning and the right filter media help maintain strong airflow and reduce energy use.

Pressure Drop

Pressure drop measures how hard your system works to push air through the filter. A high pressure drop means your filter is clogged or not compatible with your system. Monitoring pressure drop helps you spot problems early. When you keep pressure drop low, you save money and extend the life of your dust collector.

Cleaning & Maintenance

Pulse Jet

Pulse jet cleaning uses short bursts of compressed air to clean the filter bags. This method works well for most industrial dust collectors. It keeps filters clean and maintains strong airflow. Pulse jet systems are fast and efficient, making them a top choice for busy facilities.

Shaker

Shaker cleaning shakes the filter bags to remove dust. This method suits smaller systems or places without compressed air. Shaker systems are simple and reliable. They help keep your dust collector running smoothly.

Reverse Air

Reverse air cleaning uses a gentle flow of air in the opposite direction to clean the bags. This method is gentle on filter media and works well for delicate or specialty filters. Reverse air systems extend filter life and reduce wear.

Maintenance Schedule

Regular maintenance keeps your dust collector at peak performance. Follow these steps for the best results:

Monitor differential pressure every day.

Inspect filter bags weekly for dust buildup or leaks.

Check the compressed air system each month for moisture or leaks.

Assess filter bags every quarter for wear or damage.

Change filters at the intervals recommended by the manufacturer.

Maintenance Practice | Description |

Monitor Pressure Drop | Check daily to catch issues early. |

Remove Dust Frequently | Prevents buildup and extends filter life. |

Inspect Bags Thoroughly | Look for wear or leaks every week. |

Follow Proper Bag Changeout | Handle bags carefully to avoid damage. |

Track Performance Data | Keep records to plan replacements and spot trends. |

Alert: Regular inspections and cleaning prevent costly breakdowns and keep your dust collector system safe and efficient.

CPE Filters supports your maintenance plan with expert advice and custom solutions. Trust their team to help you achieve top performance and long filter life.

Compliance & Supplier Selection

Meeting industry standards is essential for every facility. The right dust collector filter bag helps you stay compliant and avoid costly penalties. Regulations protect workers and ensure safe operations. CPE Filters delivers solutions that meet strict requirements and support your business.

Industry Standards

OSHA

OSHA sets rules for worker safety. Facilities must limit exposure to airborne dust and use proper exhaust systems. OSHA compliance keeps employees safe and prevents health risks.

NFPA

NFPA 660-2025 covers dust collection system design and safety. It requires proper maintenance and explosion isolation. Following NFPA guidelines reduces fire hazards and protects your equipment.

ISO

ISO standards focus on filtration efficiency and product quality. ISO 16890 and EN 1822 set benchmarks for dust collector performance. Meeting ISO standards shows your commitment to excellence.

Standard | Description | Key Compliance Requirements |

NFPA 660-2025 | Dust collection system design and safety | System design, maintenance, explosion isolation |

OSHA | Worker exposure to airborne wood dust | Exposure limits, exhaust ventilation systems |

ATEX | Equipment design and workplace protection | Equipment safety, compliance with dust collection systems |

Note: Compliance requirements differ by industry. Food processing demands sanitary systems and GMP compliance. Pharmaceuticals focus on preventing cross-contamination. Metalworking requires air quality and safety standards. Custom dust collectors help each industry meet these needs.

Industry | Compliance Requirements |

Food Processing | Cleanliness, hygiene, sanitary dust collection, GMP compliance |

Pharmaceuticals | Prevent cross-contamination, follow specific regulations |

Metalworking | Manage hazardous dust, ensure workplace safety |

Choosing the Best Dust Collector Bag Filter Supplier

Selecting the best dust collector supplier is crucial. You need a partner who understands your needs and delivers reliable products. CPE Filters stands out with custom solutions and expert support.

Supplier Criteria

Look for suppliers who meet these criteria:

Bags must comply with ISO, EN, or ASTM standards.

Minimum 99.9% filtration efficiency at 0.3 microns.

Cost-efficient products with low replacement frequency.

Compatibility with your dust collector system.

Flame-retardant or anti-static features for high-risk environments.

Criteria | Details |

Specifications & Compliance | Bags meet ISO 16890, EN 1822, ASTM F1974 standards |

Performance & Quality Validation | Minimum 99.9% filtration efficiency at 0.3 microns |

Cost-Efficiency Analysis | Total cost of ownership, including purchase price and replacement frequency |

Integration Capabilities | Dimensional compatibility with collector housings and cages |

After-Sales Support Evaluation | Technical support and warranty terms |

Operational Safety Compliance | Flame-retardant or anti-static features for high-risk environments |

Warranty

A strong warranty protects your investment. It covers defects and ensures you get the best dust collector performance. CPE Filters offers warranties that give you peace of mind.

Support

Technical support is vital. You need fast answers and expert guidance. CPE Filters provides ongoing support and helps you solve problems quickly.

Choose a reputable supplier like CPE Filters. Their certifications, custom solutions, and support help you stay compliant and keep your facility safe.

Choosing the proper bag filter for your dust collector starts with understanding material, size, and operating conditions. Avoid common mistakes by checking airflow, dust loading, and maintenance costs. Create a checklist for regular inspections and airflow checks. Consulting experts at CPE Filters improves filter performance and ensures compliance. The right filter boosts safety, lowers energy use, and increases production output. Use advanced tools and innovations for longer filter life and reliable operation.

Parameter | Importance |

Air Volume | Determines collector size and efficiency |

Air-to-Cloth Ratio | Ensures optimal filtration |

Interstitial Velocity | Prevents clogging and maintains performance |

FAQ

What is the main purpose of a dust collector filter bag?

A filter bag traps harmful particles from the air. It keeps your facility clean and safe. It protects employees and equipment. It helps your business meet safety standards.

How often should I replace my filter bags?

Check filter bags every quarter. Replace them when you see wear, damage, or reduced performance. Regular replacement prevents costly downtime and keeps your system efficient.

Which material is best for high-temperature environments?

Aramid and PTFE materials work well in high heat. They resist thermal damage and last longer. Ask CPE Filters for advice on the best choice for your facility.

Can I use any filter bag in a chemical-rich environment?

No. Choose filter bags made from PTFE or polypropylene. These materials resist acids and solvents. Using the right bag protects your dust collector and ensures safety.

How do I know if my filter bag fits my system?

Measure the diameter and length of your collector’s housing. Check the air-to-cloth ratio. Contact CPE Filters for custom sizing and expert guidance.

What maintenance steps keep my filter bags working longer?

Monitor pressure drop daily. Clean bags regularly. Inspect for leaks and damage. Follow a maintenance schedule. These steps extend filter life and improve performance.

Why should I choose CPE Filters for my facility?

CPE Filters offers custom solutions, expert support, and reliable products. Their team helps you select the best filter bag for your needs. Improve safety and efficiency with their guidance.

Are CPE Filters’ products compliant with industry standards?

Yes. CPE Filters’ products meet OSHA, NFPA, and ISO requirements. You get peace of mind and proven performance.

Tip: Contact CPE Filters for a free consultation. Get the right filter bag and boost your facility’s safety.

Question | Quick Answer |

Best material for high heat? | Aramid or PTFE |

Replace filter bags how often? | Every quarter or as needed |

Chemical-resistant bag options? | PTFE or polypropylene |

Industry compliance? | OSHA, NFPA, ISO |