Top PPS filter bag makers like Ahlstrom-Munksjö, Filtration Group, Camfil, and BWF Envirotec are leaders in quality and new ideas. PPS filter bags work well for dust and baghouse systems. They are strong and can handle high heat. They also work with many chemicals. This makes them important for tough jobs in factories. When you look at filters, think about how well they work, how long they last, their price, and how easy they are to take care of. Cleaning dust collectors often, with help from CPE Filters experts, helps your system work better and follow the rules.

Key Takeaways

PPS filter bags are tough. They can handle high heat. They can also deal with harsh chemicals. This makes them good for hard industrial work.

Cleaning and taking care of PPS filter bags often helps them last longer. It also makes the system work better.

Picking the right filter bag material is very important. PPS has great chemical resistance. It is also more durable than other materials.

Choosing a trusted manufacturer gives you high-quality PPS filter bags. These bags meet industry rules. They also work well and are reliable.

Knowing what your factory needs helps you choose the best PPS filter bag. This makes sure you get good filtration. It also helps you follow the rules.

PPS Filter Bag Overview and Importance

![c5226bce-0f09-49ce-941d-3795199b5432 c5226bce-0f09-49ce-941d-3795199b5432]()

What Is a PPS Filter Bag

A pps filter bag is made from polyphenylene sulfide fibers. These fibers make the filter strong and reliable. It works well in tough places like factories. The pps felt can handle high heat and harsh chemicals. This is why factories use them to control dust and keep air clean. The special fiber mix gives the bag great heat and chemical resistance. These bags are perfect for baghouse systems that face hard conditions every day.

Key Properties of PPS Filter Bags:

Property | Description |

High Temperature Resistance | Handles up to 160°C (320°F), surges to 190°C (375°F) |

Chemical Resistance | Stays strong against acids, alkalis, and solvents |

Moisture Resistance | Works well in high humidity and wet settings |

Mechanical Strength | Durable and tear-resistant for long-lasting use |

Key Benefits for Industrial Filtration

pps filter bags have many good points for industrial filtration. They resist damage from acids and alkalis. This makes them great for baghouse jobs. Their strong build helps them last longer in hot places. These filters also work well in wet or chemical-heavy areas. They help factories meet strict rules and keep workers safe. pps felt can handle tough chemicals and high heat. It works better than many other filter bag materials.

Strong resistance to corrosion, alkalis, and acids

Withstands high temperatures for longer life

Robust build resists chemical and thermal damage

Suitable for high humidity and chemical exposure

PPS vs Other Filter Bag Materials

Picking the right filter bag material is important for factories. pps stands out when compared to p84, ptfe membrane filters, Nomex, and polyester. The table below shows how these materials compare in key ways:

Filter Bag Material | Filtration Efficiency | Temperature Resistance | Corrosion Resistance |

PPS | Moderate | Up to 190 °C | Excellent |

PTFE | 99.99% | High | Moderate |

Nomex | Varies | Moderate | Good |

Polyester | Varies | Up to 150 °C | Good |

P84 | High | Up to 260 °C | Excellent |

pps and p84 are both high-temperature felts. P84 can handle even higher heat. But pps is often picked for its good price, chemical resistance, and strength. pps filter bags work well in dust collection systems where other materials might not. For best results, many factories use pps or p84 in their baghouse systems. Sometimes they add ptfe membrane filters for extra safety.

Performance Comparison of Dust Collection Bag Materials

Filtration Efficiency and Micron Ratings

Factories need filters to catch very small dust. Filtration efficiency is very important for dust collection filter bags. PPS filter bags do a great job at catching dust. They meet tough rules in many industries. Some dust collection filter bags can catch dust as small as 1 micron. They can also catch bigger dust up to 200 microns. The right micron size depends on the work. For example, medicine factories need less than 10 microns. Cement factories need 25 to 50 microns to clean dust. Non-ferrous metal factories also use 25 to 50 microns.

Picking the right micron size helps your baghouse filter materials follow the rules and keep air clean.

Industry | Micron Rating |

Pharmaceutical | Less than 10 µm |

Cement | 25 to 50 µm |

Non-Ferrous Metal Production | 25 to 50 µm |

Baghouse filter materials like PPS, PTFE, Nomex, and polyester work in different ways. PPS is special because it works well and costs less. PPS filters do a good job in hard places.

Durability and Longevity

Factories want filters that last a long time. PPS filter bags are strong and last longer than many others. They do not tear or wear out fast, even when used all the time. A PPS dust collection filter bag lasts about two years. Standard polyester bags last about one year. Fiberglass bags last one to two years. PPS bags do not need to be changed often. This saves money and time.

Filter Material | Average Service Life | Downtime for Changeout | Replacement Frequency |

PPS Filter Bag | ~2 years | Up to 24 hours | Low |

Standard Polyester | ~1 year | Up to 24 hours | Medium |

Fiberglass | ~1-2 years | Up to 24 hours | Medium |

Filters that last longer mean fewer stops and lower costs.

PPS dust removal filter bag options are very strong. They keep working well after many cleanings. This makes PPS a smart pick for factories that need good filters.

Chemical and Temperature Resistance

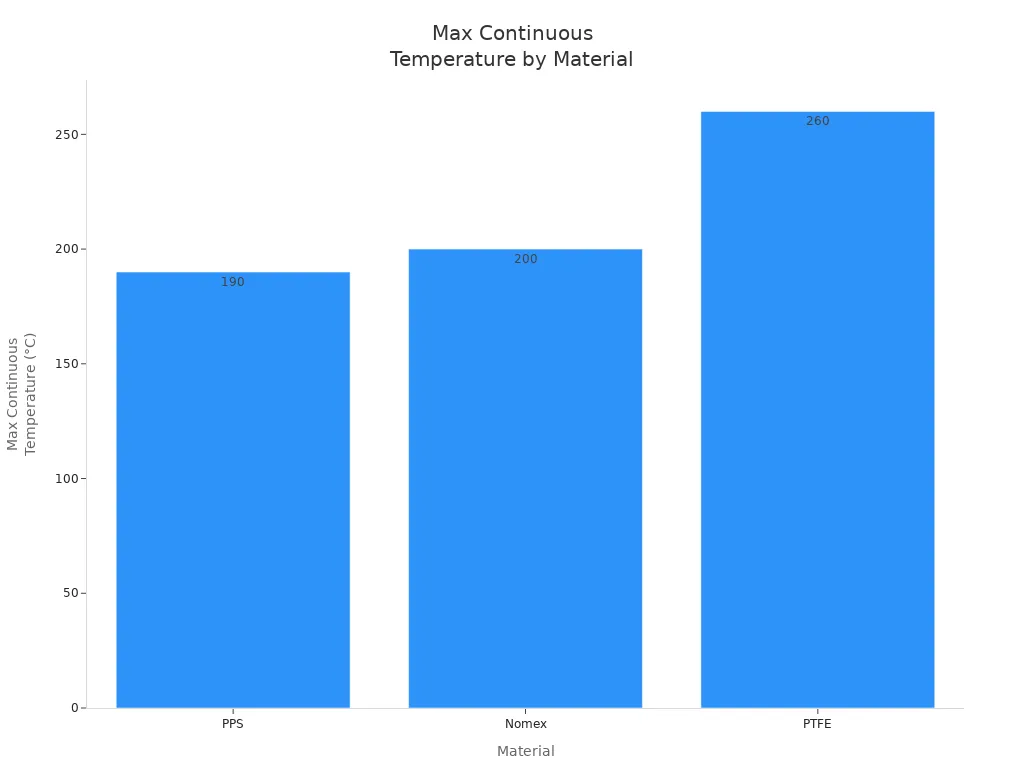

Factories sometimes have strong chemicals and high heat. PPS baghouse filter materials work well in these places. They do not get damaged by acids, alkalis, or organic solvents. PPS filters can handle heat up to 190°C all the time. They can take short bursts up to 230°C. Nomex bags can take up to 200°C, but they are not as good with chemicals. PTFE bags can take up to 260°C and are best with chemicals. Polyester bags do not resist chemicals well.

Material | Maximum Continuous Temperature | Short-term Temperature Spike | Chemical Resistance |

PPS | 190°C (374°F) | 230°C (446°F) | Excellent against acids, alkalis, and organic solvents |

Nomex | 200°C | N/A | Moderate |

PTFE | 260°C | N/A | Superior |

Polyester | N/A | N/A | Limited |

PPS baghouse filter materials do not shrink much in heat. They stay the same shape and do not bend, even when it is very hot. This helps them work well and stops leaks. PPS filters are great for factories that need strong filters in hard places.

PPS dust collection filter bag solutions give the best performance, work well, and are very reliable. They help factories follow rules and keep working without problems.

PPS Filter Bags: Top Manufacturers

Camfil PPS Filter Bags: Features and Strengths

Camfil is a well-known company in industrial filtration. Their PPS filter bag is made for hard jobs. It works in places with high heat and strong chemicals. Camfil’s PPS filter bags clean 95% of the air. This is better than Aramid, Fiberglass, and PTFE. The special material lowers pressure drop by half. This helps more air move through and saves energy. Camfil’s design helps factories spend less and work better.

PPS filter bags can take high heat and tough chemicals.

They clean 95% of the air to keep it safe.

Lower pressure drop means more air and less energy use.

Factories using Camfil PPS filter bags say they last a long time. These bags help stop costly problems. Camfil’s products need less care than others. This helps factories keep working and have less downtime.

CPE Filters PPS Filter Bags: Maintenance and Reliability

CPE Filters makes PPS filter bags that are easy to care for. They know how to keep dust collectors working well. CPE Filters has plans for regular checkups. These plans include checking, changing filters, and looking at the system. Skilled workers do all the jobs, so your baghouse works right.

CPE Filters helps stop sudden problems in factories. Their PPS filter bag lasts longer and keeps systems safe. The company’s guide lists daily, weekly, and yearly jobs. These jobs are checking pressure, looking at filter media, and watching fans. CPE Filters makes it simple to keep filters working their best.

Tip: Doing regular care with CPE Filters helps your PPS filter bag last longer and keeps your factory safe.

[Other Leading Brands]: Product Highlights

Many other brands make PPS filter bags with good features. These companies are known for quality and new ideas. The table below lists top makers and what they do well:

Manufacturer | Product Quality Features | Industry Reputation Features |

Guangdong Keskay Environmental | Uses strong PPS fibers, resists chemicals, filters well. | Good at research, keeps customers happy, very reliable. |

Donaldson Company, Inc. | Has advanced fibers, holds lots of dust, cleans easily. | Sells worldwide, tests products, gives technical help. |

Camfil AB | Built strong, saves energy, catches dust well. | Cares for the environment, makes custom solutions, has lots of experience. |

Other brands you might see are:

AOG JAPAN

HL Filter USA

Jiangsu Xinquan Environmental Protection Material Co.Ltd

Sffiltech

Shivam Filters

Entex

Suzhou Kosa Environmental Protection Co. Ltd

Unitech Glass Tech Private Limited

Stanford Advanced Materials

Zhejiang Heading Environment Technology Co. Ltd

These brands have PPS filter bags for many types of factories. They focus on cleaning well, lasting long, and working every time. Factories can pick from many filters to fit their needs. Each maker has something special, like strong fibers, chemical resistance, or great customer help.

Note: Picking a trusted maker helps your PPS filter bags last longer and keeps your baghouse working well.

Longevity and Maintenance of PPS Filter Bags

Maintenance Best Practices

Making PPS filter bags last a long time is very important. You need to take care of them often. Checking the bags helps you find problems early. Cleaning with pulse jet, shaking, or reverse air flow removes dust. This keeps the filters working well. A simple cleaning plan can stop big repairs. It also helps your baghouse last longer.

Best Practice | Description |

Regular Inspection | Check for rips, holes, or weak seams. |

Regular Cleaning | Clean off dust so the filter works well. |

Timely Replacement | Change bags when they get old or worn out. |

Taking care of your filters saves money over time. It also helps you pick the best materials for your needs.

Preventative Programs by CPE Filters

CPE Filters has special programs to help your filters last longer. Their experts make plans for daily, weekly, monthly, and yearly jobs. These plans include checking pressure, looking at the filter, and checking fans. Skilled workers do these jobs to keep your PPS filter bags working the longest.

Watching pressure helps filters last longer.

Doing regular care stops surprise problems and keeps things running.

CPE Filters’ plans save money by stopping big repairs.

Pick CPE Filters for good help and expert advice.

Common Issues and Solutions

Many things can make PPS filter bags not last as long. Some common problems are clogging, less air moving, and rips. Checking and cleaning often fixes most problems. Picking the right filter material is also important for dust, heat, and chemicals.

Clogging or less air: Check and clean bags often.

Rips or tears: Change broken bags right away.

Wrong bag material: Use the right filter for your job.

Fixing these problems fast helps your filters last longer and keeps your system working well.

Choosing the Right PPS Filter Bag for Industrial Use

Matching Filter Bag to Application Needs

Picking the right PPS filter bag starts with knowing what your factory needs. Every industry has its own problems. Steel plants, waste incinerators, power stations, and petrochemical sites need filters that can handle high heat and strong chemicals. XIECHANG makes special solutions for these places. Their dust collection systems use smart pulse valves and cloud tools to help filters work better and last longer.

Property | Description |

Chemical Resistance | Handles acids and bases in harsh environments. |

Temperature Tolerance | Works up to 190°C without losing strength. |

Industrial Applications | Used in power plants, waste incineration, and chemical processing. |

Factories should also think about how fast they need to filter, what material to use, how to clean dust, and where the filter will be used. The right baghouse filter keeps air clean and helps machines work well.

Evaluating Manufacturer Claims

Not all filter makers are the same. XIECHANG is different because they have over 30 years of experience. They have more than 300 patents and serve 40,000 customers around the world. They are part of the Baghouse Dust Collection Committee, which shows they are leaders and have new ideas. When you compare makers, look for good technical skills, quick help, and strong support after you buy. XIECHANG has won national awards and has many repeat customers. This shows they care about quality and service.

Pick a maker with a good history and helpful customer support.

Avoiding Common Pitfalls

Many people make mistakes when picking filters. Price should not be the only thing you look at. Cheap filters may break early and cost more later. Always match the filter to your dust type, airflow, and heat. Installing filters the right way and testing them stops problems. XIECHANG helps from picking the filter to fixing and keeping it working. This helps customers avoid trouble and keeps systems running well.

Think about both cost and how long the filter will last.

Make sure the filter fits your needs in size and shape.

Follow instructions for installing and check how it works.

Making smart choices means fewer problems and better results.

Top PPS filter bag brands are Parker Hannifin, MANN + HUMMEL, Donaldson Company, and Camfil AB. These brands are known for being tough, working well, and giving good help with care. The table below shows what makes each brand special:

Brand | Advantages |

Parker Hannifin | Custom engineering, global support |

MANN + HUMMEL | German excellence, abrasion resistance |

Donaldson Company | Long service life, environmental focus |

Camfil AB | Innovation, certifications |

People buying for factories should do these things for the best results:

Know what you want your filters to do and pick the right baghouse filters.

Make sure the pps material, dust type, and system design all fit together.

Plan to check and clean filters often so they work their best.

Getting help from CPE Filters experts keeps your dust collection system working well and following the rules.

FAQ

What makes PPS filter bags ideal for industrial use?

PPS filter bags can take high heat and strong chemicals. They last longer than most other filter bags. PPS is a good choice for tough factory jobs.

How often should I replace PPS filters in my system?

Change PPS filters every two years for best results. Check them often to find problems early. This helps your system work well and stops big repairs.

Can PPS filter bags improve baghouse efficiency?

Yes! PPS filter bags help baghouse systems catch more dust. They help factories follow safety rules and need less fixing.

Are PPS filter bags suitable for all types of dust?

PPS filter bags work with many kinds of dust. They can handle fine and rough dust. Factories like cement, steel, and power plants use them.

Why choose expert maintenance for PPS filter bags?

Expert care makes PPS filter bags last longer. Skilled workers stop problems and keep filters working well. Getting help from experts gives you peace of mind.