No single dust collector filter bag material works for every industry. The best material depends on the type of dust, work environment, and temperature. Some materials offer high durability, while others resist chemicals or extreme heat. See how common options compare:

Material | Usage Statistics/Market Share |

Polyester | Commonly used |

Polypropylene | Commonly used |

Aramid (Nomex) | High-temperature resistant |

Acrylic fibers | Commonly used |

Teflon (PTFE) | Increasingly popular |

Fiberglass | Commonly used |

Polyimide (P84) | Commonly used |

Choosing the right material for your dust collector filter bag improves air quality, keeps workers safe, increases equipment life, and ensures you meet regulations.

Key Takeaways

Choosing the right dust collector filter bag material is crucial for optimal filtration efficiency and air quality.

Different materials like polyester, aramid, and PTFE offer unique benefits for specific industrial applications.

Durability of filter bags reduces maintenance costs and extends service life, making material selection vital.

Compliance with safety regulations protects workers and avoids costly fines; select materials that meet industry standards.

Evaluate operating conditions, including temperature and dust characteristics, to ensure the right filter media choice.

Regular maintenance and inspections of filter bags enhance performance and prevent unexpected downtime.

Blended fabrics provide a versatile solution, combining strengths of multiple fibers for complex dust challenges.

Investing in high-quality filter bags leads to better air quality, worker safety, and long-term cost savings.

Importance of Dust Collector Filter Bag Material

Filtration Efficiency

Choosing the right dust collector filter bag material is essential for achieving high efficiency in any dust collection system. The material directly affects how well the filter captures dust and particles. Several factors influence capture efficiencies, including gas temperature, humidity, chemistry, particle size, dust concentration, filter wind speed, and dust removal method.

Material | Filtration Capability |

Nonwoven | Removes small aerosols and dust particles. |

Felted | Traps particles through impact and interception. |

Fiberglass | Performs well in extreme conditions and high temperatures. |

Different industries require specific filter materials. For example:

Selecting the proper filter material ensures the dust collector filter bag delivers optimal performance and maintains air quality. This choice helps protect workers and equipment from harmful dust.

Durability and Maintenance

The durability of dust collector filter bags depends on the material’s resistance to abrasion, temperature, and chemical exposure. A strong filter material lasts longer and reduces maintenance needs. When you select a filter bag that withstands harsh conditions, you minimize cleaning and replacement costs.

Understanding the strengths of each filter material is vital for optimizing dust collection system performance. For example, some filters resist high temperatures, while others handle chemical exposure better. The right filter material keeps the system running smoothly and prevents unexpected downtime.

Compliance and Safety

Regulatory standards require industries to use dust collector filter bags that meet strict safety and compliance guidelines. Manufacturing and industrial facilities must contain dust and follow hazardous material handling rules. Construction sites need dust control measures to comply with local air quality regulations. Pharmaceutical and food processing industries must use filters that meet cleanliness standards and Good Manufacturing Practices. Mining operations must follow MSHA regulations for dust control. Energy and power generation facilities often use HEPA filters to meet emission limits for particulate matter.

Selecting the correct filter material ensures compliance with these regulations. It also protects workers and the environment from dangerous dust exposure. The right filter material supports workplace safety and helps avoid costly fines or shutdowns.

Tip: Always match the filter material to your industry’s requirements and environmental conditions. This step guarantees high efficiency, durability, and compliance.

Overview of Fabric Filter Dust Collectors and Bag Materials

Fabric filter dust collectors play a vital role in industrial dust management. These systems use filter media to capture dust and particles from the air, improving workplace safety and air quality. Industries rely on fabric filter dust collectors to meet strict regulations and protect workers from harmful exposure.

The main types of dust collectors include baghouse, cartridge, cyclone, electrostatic precipitators, and wet scrubbers. Each type uses different filter media to achieve high capture efficiency and suit specific industrial needs.

Type | Function | Key Features |

Baghouse | Uses fabric filter bags to capture dust particles efficiently. | Up to 99% capture efficiency, suitable for various industries, requires maintenance. |

Cartridge | Utilizes cylindrical cartridges for high-efficiency filtration. | Over 99% capture rate for fine particles, compact design, frequent filter changes needed. |

Cyclone | Employs centrifugal force to separate larger dust particles from air. | Effective for particles >10 micrometers, low maintenance, best for heavy dust. |

Electrostatic Precipitators | Uses electric charges to capture fine dust particles. | More than 99% efficiency, suitable for high-temperature environments, requires cleaning. |

Wet Scrubbers | Uses liquid to capture heavy dust particles effectively. | Handles abrasive dust, high water use, continuous maintenance required. |

Choosing the right filter media is essential for maximizing efficiency and minimizing maintenance. The filter media must match the dust type, temperature, and chemical exposure in each application. Let’s explore the most common filter media used in industrial dust collector bags.

Polyester (PE)

Polyester filter media is the most popular choice for fabric filter dust collectors. This filter media offers excellent durability and resistance to abrasion. Polyester filter media performs well in moderate temperature environments and handles a wide range of dust types. Many industries prefer polyester filter media because it provides reliable filtration and cost-effective performance. Polyester filter media is easy to clean and maintain, making it ideal for general-purpose applications. The filter media resists moisture and maintains its structure over time. Polyester filter media supports compliance with air quality standards and keeps operations running smoothly.

Polypropylene (PP)

Polypropylene filter media stands out for its superior chemical resistance. This filter media is perfect for environments with acids, solvents, or corrosive dust. Polypropylene filter media is lightweight and flexible, allowing for easy installation and replacement. The filter media works well in lower temperature settings and offers good filtration efficiency. Polypropylene filter media is often used in chemical processing plants and industries where aggressive dust is present. The filter media does not absorb moisture, which prevents clogging and extends bag life. Polypropylene filter media helps maintain compliance and reduces downtime in demanding conditions.

Aramid (Nomex®)

Aramid filter media, known as Nomex®, is engineered for high-temperature applications. This filter media withstands extreme heat and provides flame resistance. Aramid filter media is ideal for steel plants, foundries, and power generation facilities. The filter media maintains its strength and filtration efficiency even under harsh conditions. Aramid filter media resists abrasion and chemical attack, ensuring long service life. Industries choose aramid filter media when safety and durability are top priorities. The filter media supports regulatory compliance and protects workers from hazardous dust.

Note: Selecting the right filter media for your dust collector bags ensures optimal performance, safety, and compliance. Consult with experts to match filter media properties to your specific industrial needs.

PTFE (Teflon®)

PTFE, also known as Teflon®, stands out as a premium choice for dust collector filter bags in demanding industrial environments. This material delivers unmatched chemical resistance and non-stick properties. PTFE filter bags perform exceptionally well in settings where aggressive chemicals, sticky dust, or high humidity threaten other materials. Industries such as chemical processing, pharmaceuticals, and food manufacturing rely on PTFE for its ability to maintain filtration efficiency under harsh conditions.

Key Benefits of PTFE (Teflon®):

Handles continuous temperatures up to 260°C (500°F)

Resists acids, alkalis, solvents, and moisture

Prevents dust cake buildup due to its slick surface

Offers long service life, reducing replacement frequency

Feature | PTFE (Teflon®) Advantage |

Chemical Resistance | Excellent |

Temperature Tolerance | Up to 260°C (500°F) |

Moisture Resistance | Outstanding |

Cleaning Ease | Superior |

Tip: Choose PTFE filter bags for processes with corrosive gases or sticky dust. This investment pays off with fewer shutdowns and lower maintenance costs.

Fiberglass

Fiberglass filter bags provide a robust solution for industries facing extreme temperatures and fine particulate challenges. This material excels in power generation, cement production, and metalworking, where dust collectors must withstand continuous high heat. Fiberglass maintains its structural integrity and filtration performance even when exposed to temperatures up to 260°C (500°F).

Why Fiberglass?

Withstands thermal shock and high temperatures

Filters fine particles efficiently

Maintains strength in harsh environments

Fiberglass filter bags often receive special coatings or finishes. These enhancements improve abrasion resistance and extend bag life. When you need reliable filtration in high-heat applications, fiberglass delivers consistent results.

Note: Fiberglass is ideal for baghouses in boilers, kilns, and incinerators. It keeps your operation compliant and your air clean.

Acrylic

Acrylic filter bags offer a smart solution for environments with acidic gases and moderate temperatures. This material resists hydrolysis and acid attack, making it a popular choice in chemical plants, waste incineration, and fertilizer production. Acrylic filter bags provide stable filtration performance and help maintain regulatory compliance.

Advantages of Acrylic Filter Bags:

Good resistance to acids and moisture

Operates effectively up to 130°C (266°F)

Delivers reliable dust capture in challenging conditions

Application Area | Acrylic Filter Bag Benefit |

Chemical Processing | Acid resistance |

Waste Incineration | Moisture tolerance |

Fertilizer Plants | Consistent filtration |

Call to Action: Upgrade to acrylic filter bags if your process involves acidic dust or fluctuating humidity. Protect your equipment and ensure smooth, compliant operations.

Blended Fabrics

Blended fabrics bring together the strengths of multiple fibers to create high-performance dust collector filter bags. These materials combine the best features of polyester, aramid, acrylic, polypropylene, and other fibers. This approach delivers a filter bag that can handle a wide range of industrial challenges.

Why choose blended fabrics for your dust collector bags?

Blended fabrics offer a unique balance of durability, chemical resistance, and temperature tolerance. You get the flexibility to match your filter bag to your exact needs. For example, a blend of polyester and aramid can provide both abrasion resistance and high-temperature performance. This means your dust collector bags last longer and require less maintenance.

Tip: If your facility faces changing dust types or fluctuating temperatures, blended fabrics adapt quickly. You do not need to switch out bags for every new challenge.

Key Benefits of Blended Fabrics

Custom Performance: Manufacturers can design blends for specific applications. You get a filter bag that fits your process, not a one-size-fits-all solution.

Extended Bag Life: Blended fabrics resist wear and tear better than single-fiber bags. This reduces replacement costs and downtime.

Improved Filtration: Combining fibers can boost filtration efficiency. You capture more dust and keep your air cleaner.

Versatility: Blended fabrics work in many industries, from cement plants to food processing.

Fiber Blend Example | Main Advantage | Typical Application |

Polyester + Aramid | Heat and abrasion resistance | Metalworking, foundries |

Acrylic + Polypropylene | Acid and moisture resistance | Chemical, fertilizer plants |

Polyester + PTFE | Enhanced chemical and temperature resistance | Power generation, incinerators |

Blended fabrics also benefit from the latest technology. Many now feature surface treatments or nanofiber coatings. These upgrades make cleaning easier and improve dust release. You get better performance with less effort.

Call to Action: Upgrade your dust collector system with blended fabric filter bags. Protect your workers, meet regulations, and lower your operating costs. Contact a dust collection expert today to find the perfect blend for your operation.

Blended fabrics give you the power to solve complex dust collection problems. Choose a material that adapts to your needs and delivers reliable results every day.

Comparison of Dust Collector Filter Bag Materials

Tensile Strength

Tensile strength measures how much force a filter bag can handle before it breaks. This property is critical for any dust collection system. High tensile strength means the filter bag will last longer, even in tough industrial environments. Polyester and aramid media stand out for their strong fibers. These materials resist tearing and stretching during dust testing and regular operation. Fiberglass also offers impressive strength, especially when used in high-temperature settings.

When you choose a dust collector filter bag with high tensile strength, you reduce the risk of bag failure. This leads to fewer shutdowns and lower maintenance costs. Reliable filter bag performance keeps your operation running smoothly and protects your investment.

Tip: Always check the tensile strength ratings during filter bag testing. Stronger bags mean better quality and longer service life.

Chemical Resistance

Chemical resistance is a key factor in filter bag performance. Different industries face unique chemical challenges. The right filter media will resist acids, alkalis, and solvents, ensuring consistent dust collection and high-quality air.

Here is a comparison of chemical resistance and temperature limits for common filter bag materials:

Filter Bag Material | Temperature Resistance | Chemical Resistance Characteristics | Applications |

Polypropylene (PP) | Medium temperatures | Good acid and alkali resistance, especially to wet acids and strong alkalis | General-purpose use |

PPS | Up to 160℃ (long-term), 190℃ (short-term) | Excellent chemical corrosion resistance | High-temperature and corrosive flue gases |

P84 | Up to 260℃ | Excellent chemical resistance, wear and stretching resistance | High-temperature industrial environments |

Aramid | Up to 200℃ | Poor hydrolytic stability, sensitive to humid flue gas | Dry, high-temperature environments |

Fiberglass | Up to 280℃ | Outstanding chemical stability, not wear-resistant | Harsh environments, high-temperature flue gas |

PTFE | Up to 260℃ | Acid and alkali resistance, excellent chemical stability | High-precision filtration in corrosive environments |

Polypropylene filter bags excel in chemical plants because they resist acids and alkalis. PTFE media offers the highest level of chemical stability, making it the top choice for aggressive dust and harsh gases. Fiberglass and P84 also provide excellent chemical resistance, especially in high-temperature applications. Aramid works best in dry, hot environments but is less stable in humid or wet conditions.

Note: For the best filter bag performance, match the chemical resistance of your filter media to the chemicals present in your dust testing results.

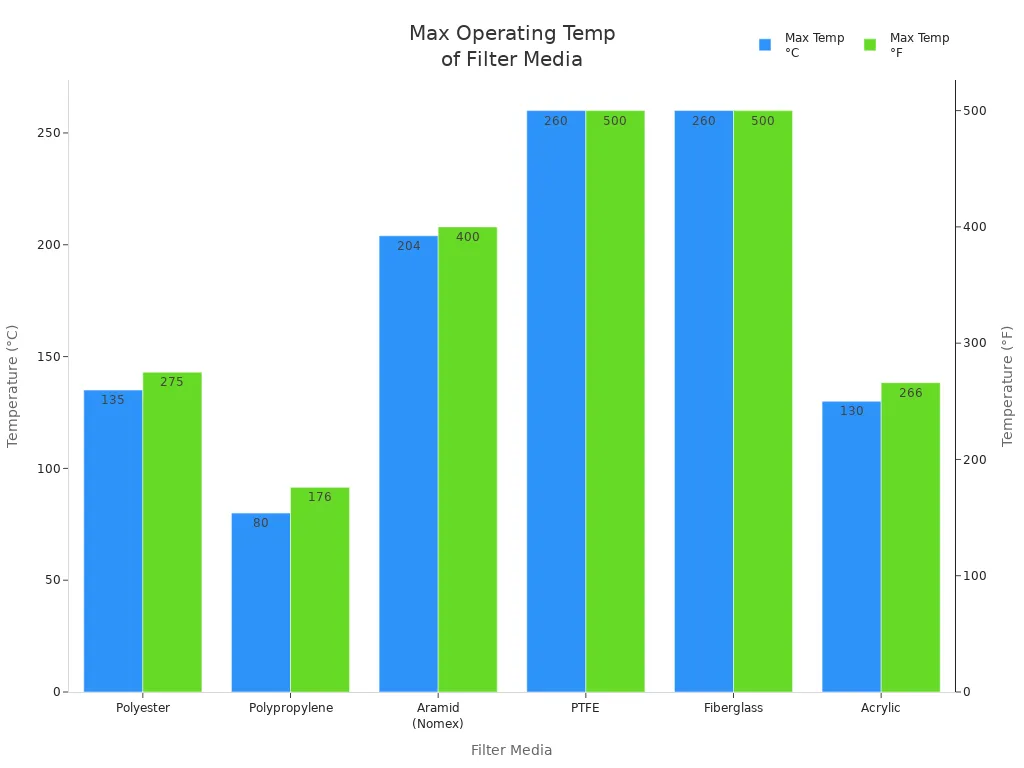

Temperature Tolerance

Temperature tolerance determines how well a filter bag performs under heat. Each filter media has a maximum operating temperature. Exceeding this limit can damage the filter and reduce dust collection efficiency. Choosing the right media for your process temperature is essential for safety and quality.

Here is a table showing the maximum operating temperatures for common filter bag materials:

Filter Media | Maximum Operating Temperature (°C) | Maximum Operating Temperature (°F) |

Polyester | 135 | 275 |

Polypropylene | 80 | 176 |

Aramid (Nomex) | 204 | 400 |

PTFE | 260 | 500 |

Fiberglass | 260 | 500 |

Acrylic | 130 | 266 |

PTFE and fiberglass filter bags lead the market for high-temperature resistance. These media can handle up to 260°C (500°F) without losing quality. Aramid filter bags also perform well in hot environments, making them ideal for foundries and power plants. Polyester and acrylic are better for moderate temperatures, while polypropylene is best for cooler processes.

Call to Action: Upgrade your dust collector filter bags to match your process temperature. Protect your equipment, improve filter bag performance, and ensure top-quality dust collection.

Moisture Resistance

Moisture can ruin dust collector filter bags. Water vapor, humidity, or wet dust can cause filter bags to clog, weaken, or even fail. Moisture resistance is a key factor when choosing the right filter bag material for your operation.

Some materials handle moisture better than others. Polyester and polypropylene both resist water and keep their shape in damp conditions. PTFE (Teflon®) stands out for its outstanding moisture resistance. It does not absorb water and keeps dust from sticking to the bag surface. Acrylic also performs well in humid or wet environments, especially where acidic gases are present.

Fiberglass and aramid (Nomex®) do not perform as well with moisture. These materials can lose strength or become damaged if exposed to water or high humidity for long periods. If your process involves steam, wet dust, or fluctuating humidity, you need a filter bag that can handle these challenges.

Here is a quick comparison of moisture resistance for common filter bag materials:

Filter Bag Material | Moisture Resistance | Best Use Case |

Polyester | Good | General industry, food, mining |

Polypropylene | Excellent | Chemical, fertilizer plants |

PTFE (Teflon®) | Outstanding | Pharmaceuticals, sticky dust |

Acrylic | Very Good | Acidic, humid environments |

Aramid (Nomex®) | Fair | Dry, high-temperature areas |

Fiberglass | Poor | Dry, high-heat applications |

Tip: If your facility deals with wet dust or high humidity, invest in filter bags with high moisture resistance. This choice prevents clogging, reduces maintenance, and keeps your dust collection system running at peak performance.

Moisture-resistant filter bags protect your equipment and help you avoid costly downtime. They also support compliance with air quality standards by ensuring consistent dust capture, even in tough conditions.

Application Suitability by Industry

Cement Industry

The cement industry produces large amounts of fine, abrasive dust. This dust can damage equipment and harm workers if not controlled. Choosing the right dust collector filter bag is essential for safety and compliance.

Bag filters are a top choice in cement plants. These textile filters use compressed air jets to clean themselves. They work well for dry dust and keep emissions low.

Modern bag filters can achieve emissions as low as 10 mg/Nm³. This meets strict environmental standards and keeps air clean.

The best results come from matching the filter bag material to the dust’s physical properties, such as particle size and electrical resistivity.

Polyester and aramid (Nomex®) filter bags are popular in cement plants. Polyester offers durability and cost savings for general dust. Aramid handles high temperatures near kilns and clinker coolers. Fiberglass is also used for extreme heat. These materials help cement plants run efficiently and avoid costly shutdowns.

Tip: Upgrade to advanced bag filters to reduce dust emissions and protect your workers.

Chemical Processing

Chemical processing environments expose dust collector bags to acids, solvents, and high temperatures. The right filter bag material can make or break your operation.

Synthetic fabrics like polyester fleece are a smart choice for many chemical plants. They resist acids and last longer at lower temperatures (below 120°C). For hotter processes, glass cloth filter bags perform well up to 250°C. Polypropylene is another strong option, offering excellent resistance to acids and alkalis.

Each material has its strengths. Polyester fleece is durable and affordable. Polypropylene stands up to harsh chemicals. Glass cloth handles extreme heat. However, some chemicals can degrade certain materials, so always check compatibility with your process.

Note: Select filter bags based on the chemicals and temperatures in your plant. This step prevents bag failure and keeps your operation safe.

Food and Beverage

Food and beverage plants must meet strict hygiene and safety rules. Dust collector filter bags play a key role in keeping products pure and workers safe.

Challenge | Description |

Compliance with regulations | Choose suppliers who understand food safety laws. |

Filter longevity | Use durable filters to reduce replacements and lower costs. |

Environmental factors | Pick eco-friendly filters to protect the environment. |

Material | Applications in Food & Beverage | Advantages |

Polypropylene | Mild chemical resistance, hygiene focus | Exceptional chemical resistance, lightweight |

Nomex | No chemical contamination risk | Superior thermal stability, long life |

Polypropylene filter bags are ideal for processes needing chemical resistance and cleanliness. Nomex filter bags offer durability and thermal stability without risking contamination. Both materials help companies meet regulations and keep food safe.

Call to Action: Invest in high-quality filter bags to ensure product safety and reduce downtime in your food or beverage facility.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing demands the highest standards for air quality and contamination control. Dust collector filter bags play a critical role in keeping production areas clean and safe. The right filter bag material can help you meet strict regulatory requirements and protect both products and workers.

Key Challenges in Pharmaceutical Manufacturing:

Preventing cross-contamination between batches

Capturing fine powders and active pharmaceutical ingredients (APIs)

Meeting FDA, GMP, and other regulatory standards

Recommended Filter Bag Materials:

Material | Main Benefit | Typical Use Case |

PTFE (Teflon®) | Superior chemical resistance, non-stick surface | High-purity environments, sticky dust |

Polyester (PE) | Reliable filtration, easy cleaning | General dust collection |

Polypropylene (PP) | Excellent moisture and chemical resistance | Wet granulation, solvent handling |

Acrylic | Good acid resistance, stable performance | Coating and tablet production |

PTFE (Teflon®) filter bags stand out in pharmaceutical plants. They resist aggressive chemicals and prevent dust from sticking. This means less downtime for cleaning and lower risk of contamination. Polyester filter bags offer dependable performance for general dust collection. They are easy to clean and maintain, which helps keep your facility running smoothly.

Polypropylene filter bags work well in areas with high humidity or chemical exposure. They do not absorb moisture, so they stay effective even in wet processes. Acrylic filter bags provide extra protection in acidic environments, such as tablet coating rooms.

Tip: Always choose filter bags that meet FDA and GMP standards. This ensures your products stay pure and your facility passes inspections.

Why Material Selection Matters:

The wrong filter bag can lead to product recalls or failed audits.

Proper material selection reduces maintenance and replacement costs.

High-quality filter bags improve worker safety and air quality.

Action Steps for Pharmaceutical Facilities:

Assess your dust type and process conditions.

Consult with a dust collection expert.

Select filter bags with proven performance in pharmaceutical settings.

Schedule regular filter bag inspections and replacements.

Call to Action: Protect your pharmaceutical products and reputation. Invest in high-performance dust collector filter bags designed for your industry. Contact a dust collection specialist today to find the best solution for your facility.

Choosing the right filter bag material is not just about compliance. It is about ensuring the safety, quality, and efficiency of your pharmaceutical operations. Make the smart choice for your business and your team.

Mining and Woodworking

Mining and woodworking industries face unique dust challenges every day. Fine particles, abrasive dust, and fluctuating moisture levels can damage equipment and put workers at risk. Choosing the right dust collector filter bag material is the key to safe, efficient, and compliant operations.

Mining Industry Needs:

Mining operations generate large volumes of abrasive dust from crushing, grinding, and material handling. This dust can wear out filter bags quickly. It can also contain silica or other hazardous particles that threaten worker health. Mining sites often deal with high humidity, temperature swings, and harsh chemicals.

Best Filter Bag Materials for Mining:

Material | Key Benefit | Typical Mining Application |

Polyester (PE) | Abrasion resistance | Crushing, conveying, screening |

Aramid (Nomex®) | High-temperature tolerance | Smelting, roasting, kilns |

Polypropylene | Chemical resistance | Wet processing, leaching |

PTFE (Teflon®) | Non-stick, chemical proof | Aggressive or sticky dust |

Blended Fabrics | Custom performance | Mixed dust, variable conditions |

Polyester filter bags stand up to abrasive dust and offer long service life. Aramid (Nomex®) handles high heat near smelters and kilns. Polypropylene resists acids and alkalis in wet processing. PTFE (Teflon®) keeps sticky or aggressive dust from clogging the filter. Blended fabrics combine these strengths for tough mining environments.

Tip: Upgrade to abrasion-resistant or surface-treated filter bags to cut downtime and lower replacement costs in mining.

Woodworking Industry Needs:

Woodworking shops and mills produce fine sawdust, wood chips, and resinous particles. These can clog filters and create fire hazards. Moisture from green wood or humid air can also affect filter performance.

Best Filter Bag Materials for Woodworking:

Polyester (PE): Handles fine dust, resists abrasion, and is easy to clean.

Acrylic: Performs well in humid conditions and resists hydrolysis.

Blended Fabrics: Adapt to changing dust loads and moisture levels.

Polyester filter bags are the top choice for woodworking. They capture fine sawdust and last longer, even with heavy use. Acrylic bags work well in humid shops or where moisture is a concern. Blended fabrics offer flexibility for shops with mixed dust or changing conditions.

Challenge | Solution |

Fine sawdust | Polyester or blended fabrics |

Resinous dust | PTFE-coated polyester |

High humidity | Acrylic or polypropylene |

Call to Action: Protect your workers and equipment. Invest in high-quality dust collector filter bags designed for mining and woodworking. Contact a dust collection expert to find the best material for your operation.

The right filter bag material means cleaner air, safer workplaces, and fewer shutdowns. Make the smart choice for your industry today.

How to Select the Right Dust Collector Filter Bag

Assessing Operating Conditions

Every dust collector decision starts with a careful look at your operating environment. The right filter media selection depends on more than just the type of dust. You must consider temperature, airflow, and the demands of your dust collection system. Follow this practical framework to guide your selection:

Understand Your Dust & Process Environment

Begin by identifying the dust you need to capture. Look at particle size, how abrasive the dust is, and if there is any moisture present. These factors affect which filter media will last and perform best.

Define Your Airflow & Load Requirements

Measure the airflow (CFM) your system needs. Check how much dust your process creates. High dust loads or strong airflow may require tougher filter bags or special cleaning methods.

Match Collector Type & Cleaning Method to Operational Needs

Choose a dust collector filter bag that fits your collector type. Some systems use pulse-jet cleaning, while others use mechanical shaking or reverse air. The cleaning method impacts which filter media will deliver the best efficiency and lifespan.

Tip: Always review your operating conditions before making a filter selection. This step prevents costly mistakes and keeps your dust collection system running smoothly.

Evaluating Dust Characteristics

Not all dust is the same. The properties of your dust should drive your filter media selection. Consider these key points:

The size and shape of dust particles matter. Fine powders need different filter media than coarse, heavy dust.

Abrasive dust can wear out standard filter bags quickly. For these situations, select filter media engineered for durability.

Sticky or oily dust may require filter bags with special surface treatments or coatings to prevent clogging and maintain high efficiency.

Understanding the chemical makeup of your dust is also critical. Some dust contains acids, alkalis, or solvents that can damage certain filter materials. Choose a filter media that resists the chemicals in your process. This step protects your investment and ensures consistent performance.

Note: The right filter media selection improves air quality concerns and helps your facility meet safety standards.

Regulatory and Safety Requirements

Regulations protect workers and the environment from harmful dust exposure. Your filter selection must meet all local, state, and federal rules. Review these requirements before you choose a dust collector filter bag:

Check for industry-specific standards, such as OSHA, MSHA, or FDA guidelines.

Make sure your filter media selection supports compliance with emission limits and air quality concerns.

Select filter bags that are certified for use in your industry, especially in food, pharmaceutical, or hazardous dust applications.

Consult with dust collection experts to stay updated on the latest technology and regulatory changes. Advanced filter media, such as nanofiber coatings or surface treatments, can help you achieve higher efficiency and longer bag life. These innovations make compliance easier and reduce maintenance costs.

Call to Action: Do not risk fines or shutdowns. Choose dust collector filter bags that meet all safety and regulatory requirements. Protect your workers and your business with the right filter media selection.

Balancing Performance and Cost

Selecting the right dust collector filter bag is not just about performance. Cost matters, too. You want a filter bag that delivers reliable filtration without breaking your budget. Smart buyers look for value, not just the lowest price.

Key Factors to Consider:

Initial Cost: Some materials cost more upfront. PTFE and aramid bags are premium options. Polyester and polypropylene offer affordable solutions.

Service Life: A filter bag that lasts longer saves money over time. Durable materials reduce replacement frequency and maintenance costs.

Filtration Efficiency: High-efficiency bags capture more dust. This keeps your workplace safe and helps you meet regulations.

Maintenance Needs: Easy-to-clean bags lower labor costs. Surface treatments and nanofiber coatings make cleaning faster and simpler.

Downtime Reduction: Reliable filter bags prevent unexpected shutdowns. Less downtime means higher productivity and profits.

Tip: Do not focus only on price. Consider the total cost of ownership, including maintenance, replacement, and downtime.

Performance vs. Cost Comparison Table

Material | Upfront Cost | Service Life | Filtration Efficiency | Maintenance Needs | Typical Value |

Polyester (PE) | Low | Medium | Good | Easy | High |

Polypropylene | Low | Medium | Good | Easy | High |

Aramid (Nomex®) | High | Long | Excellent | Moderate | Very High |

PTFE (Teflon®) | Highest | Longest | Outstanding | Easiest | Exceptional |

Fiberglass | Medium | Long | Excellent | Moderate | High |

Acrylic | Medium | Medium | Good | Easy | High |

Blended Fabrics | Medium-High | Long | Excellent | Easy | Very High |

How to Maximize Value:

Analyze Your Process Needs: Choose a filter bag that matches your dust type, temperature, and chemical exposure.

Invest in Advanced Materials: Surface treatments and nanofiber coatings boost efficiency and extend bag life.

Consult with Experts: Get advice from dust collection specialists. They help you select the best material for your operation.

Calculate Long-Term Savings: Look beyond the purchase price. Factor in maintenance, replacement, and downtime costs.

Call to Action: Upgrade your dust collector filter bags today. Protect your workers, improve air quality, and save money in the long run. Contact a dust collection expert to find the best solution for your facility.

Balancing performance and cost ensures you get the most out of your dust collection system. Make a smart investment. Choose filter bags that deliver safety, compliance, and value.

Common Mistakes in Dust Collector Filter Bag Selection

Selecting the right dust collector filter bag is not just about choosing a material. Many facilities make costly mistakes that reduce efficiency, increase downtime, and put worker safety at risk. Avoiding these common errors will help you get the most out of your dust collection system.

Overlooking Temperature Limits

One of the biggest mistakes is ignoring the temperature limits of your filter bags. When bags are exposed to temperatures above their rated capacity, they break down much faster. This leads to early failure and poor filtration. You may notice more dust escaping into the air, which can cause health and safety problems. Always check the maximum temperature rating for your filter material and monitor your system’s operating conditions. This simple step protects your investment and keeps your operation running smoothly.

Tip: Never assume all filter bags can handle the same heat. Match the filter to your process temperature for longer life and better performance.

Ignoring Chemical Compatibility

Another frequent error is failing to consider the chemicals present in your process. Some chemicals can attack filter materials, causing them to become brittle or develop holes. This weakens the filter and allows dangerous dust to escape. The table below shows how different chemicals can affect filter bags:

Chemical Type | Effects on Filter Bags |

Corrosive Gases | Brittleness, fiber breakdown |

Acid Mists | Discoloration, pinholes |

Harsh Conditions | Chemical attack leading to degradation |

Always match your filter material to the chemicals in your environment. If you are unsure, consult with a dust collection expert. The right choice will prevent costly damage and keep your facility compliant with safety regulations.

Neglecting Maintenance Needs

Many companies overlook the importance of regular maintenance for their filter bags. Skipping inspections or cleaning schedules can lead to several problems:

Reduced filtration efficiency and higher emissions

Increased risk of equipment failures and unexpected downtime

Higher costs from inefficiency and possible fines for non-compliance

Re-entrainment of collected particles back into the air

Lower air quality and health risks for employees

A well-maintained filter system captures more dust and keeps your workplace safe. Schedule routine checks and replace filter bags before they fail. This proactive approach saves money and supports continuous production.

Note: Investing in proper filter maintenance pays off with fewer shutdowns and better air quality.

Avoid these common mistakes to maximize the performance and lifespan of your dust collector filter bags. Make smart choices, follow best practices, and protect your workers and equipment.

Selecting the right dust collector filter bag ensures clean air, safety, and efficiency. The table below highlights how dust collector filter bags offer high capacity and effective fine dust capture, making them ideal for demanding environments.

Feature | Cartridge Filters | Dust Collector Bags |

Capacity | Limited | High, handles more dust |

Filtration Efficiency | Various | Excellent for fine dust |

Clean Air | Good | Outstanding |

For best results, choose dust collector filter bags based on temperature, chemical resistance, and abrasion. Always match bag size to your system and select the right micron rating for clean air. Consult experts and consider custom options for unique dust challenges. Prioritize workplace safety and compliance to protect your team and maintain clean air.

FAQ

What is the most durable dust collector filter bag material?

Fiberglass and aramid (Nomex®) offer outstanding durability. These materials withstand extreme temperatures and abrasive dust. Choose them for long-lasting performance and fewer replacements.

How do I know which filter bag material suits my industry?

Consult a dust collection expert. Review your dust type, temperature, and chemical exposure. Use a material comparison table to match your needs. The right choice boosts efficiency and compliance.

Can filter bags handle wet or sticky dust?

PTFE (Teflon®) and polypropylene resist moisture and sticky dust. These materials prevent clogging and simplify cleaning. Upgrade your system for reliable performance in humid or challenging environments.

Are blended fabrics better than single-fiber filter bags?

Blended fabrics combine strengths of multiple fibers. They deliver custom performance, extended bag life, and improved filtration. Select blended fabrics for complex dust challenges and changing conditions.

How often should I replace dust collector filter bags?

Inspect filter bags regularly. Replace them when you notice reduced filtration, visible damage, or increased emissions. Investing in high-quality bags extends service life and lowers maintenance costs.

Do filter bag materials affect regulatory compliance?

Yes. The right material ensures your facility meets air quality standards and safety regulations. Choose certified filter bags to avoid fines and protect workers.

What advancements improve filter bag performance?

Surface treatments and nanofiber coatings enhance filtration efficiency and dust release. These innovations reduce maintenance and maximize bag life. Upgrade to advanced filter bags for superior results.